Electronic measuring equipment (EME) is transforming auto repairs by providing mechanics with advanced tools to accurately diagnose and fix various vehicle issues, from subtle problems like tire pressure checks to complex electrical system analysis. Integrating algorithms and sensors, EME enhances workshop efficiency, accuracy, and record-keeping, particularly in car paint repair scenarios. Future advancements will empower EME to offer real-time data analysis, remote monitoring, and predictive maintenance, driving the industry towards automation and data-driven decision making for improved customer satisfaction.

The automotive industry’s relentless march towards digitalization has made electronic measuring equipment (EME) an indispensable tool for auto repairs. This article delves into the multifaceted role of EME, providing a primer on its understanding and operation in modern diagnostic procedures. We explore key functions and benefits, highlighting how these devices streamline repairs, enhance accuracy, and contribute to the industry’s digital transformation. Furthermore, we peek into future trends, anticipating the evolving role of EME in shaping the automotive repair landscape.

- Understanding Electronic Measuring Equipment: A Primer for Auto Repairs

- Key Functions and Benefits in Modern Automotive Diagnostics

- Future Trends: Evolving Role of EME in the Industry's Digital Transformation

Understanding Electronic Measuring Equipment: A Primer for Auto Repairs

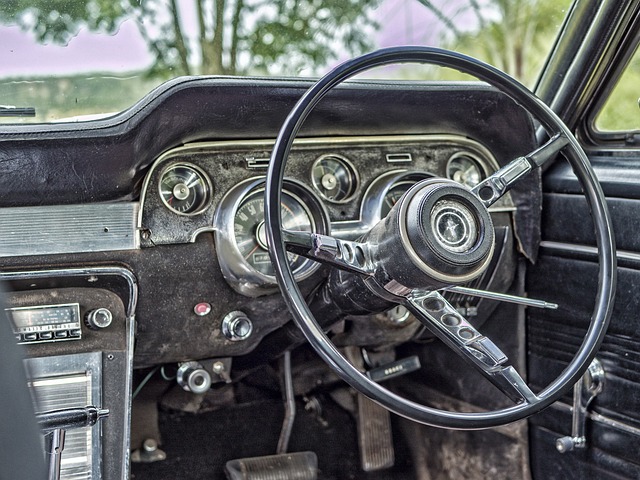

In the realm of auto repairs, electronic measuring equipment has emerged as an indispensable toolset for technicians. This technology encompasses a range of devices designed to accurately assess and diagnose various aspects of a vehicle’s systems, from engine performance to tire services and even complex auto body shop repairs. By providing precise measurements, these tools enable mechanics to pinpoint issues with greater efficiency, ensuring more accurate and timely repairs.

Understanding electronic measuring equipment involves grasping its ability to detect subtle anomalies that might be invisible to the naked eye or traditional methods. Modern auto body shop services rely on these gadgets for everything from checking tire pressure and suspension alignment to analyzing electrical systems and identifying leaks in the climate control unit. This technology empowers technicians to make informed decisions, ultimately enhancing the quality and safety of vehicle repairs.

Key Functions and Benefits in Modern Automotive Diagnostics

In today’s modern automotive landscape, electronic measuring equipment plays a pivotal role in diagnostics and repairs. These advanced tools have revolutionized how mechanics approach car body repair and auto detailing, enabling them to pinpoint issues with precision. By integrating complex algorithms and sensors, they can detect even the subtlest anomalies, from electrical faults to structural damage, thus facilitating more effective and efficient troubleshooting.

Furthermore, electronic measuring equipment offers a myriad of benefits. It facilitates faster and more accurate diagnoses, reducing the time spent on manual inspections. This not only enhances workshop productivity but also minimizes the risk of human error. Moreover, these tools often provide detailed data logs, allowing for better record-keeping and enabling mechanics to track repairs over time, which is particularly valuable in complex car paint repair scenarios.

Future Trends: Evolving Role of EME in the Industry's Digital Transformation

The future of auto repairs is closely tied to the digital transformation of the industry, and electronic measuring equipment (EME) will continue to play a pivotal role in this evolution. As technology advances, EME is expected to become even more sophisticated, offering automotive body shops unprecedented precision and efficiency. This includes the development of smart tools that can integrate with diagnostic systems, providing real-time data analysis for faster decision-making during auto detailing and restoration processes.

With the rise of connected vehicles and the Internet of Things (IoT), EME will likely be equipped to monitor vehicle performance remotely, predict maintenance needs, and facilitate remote diagnostics. This shift towards a more automated and data-driven approach in the automotive industry will not only enhance the accuracy of repairs but also enable auto body restoration professionals to stay ahead of potential issues, ultimately improving customer satisfaction across the board.

Electronic measuring equipment (EME) is revolutionizing auto repairs, offering precise diagnostics and efficient solutions. From understanding vehicle systems to navigating complex repairs, EME provides invaluable insights. As technology advances, its role will only grow, enabling mechanics to keep pace with modern vehicles’ digital landscapes. Embracing these innovations ensures a smoother, more accurate repair process, enhancing customer satisfaction in the evolving automotive industry.