Electronic measuring equipment, including laser scanners and digital calipers, revolutionizes collision repairs by offering precise damage assessments and accurate measurements for dent repairs, hail damage, and auto glass. This technology streamlines workflows, increases efficiency, enhances accuracy, and minimizes errors in both automotive body shops and luxury vehicle repair centers, ensuring superior aesthetic and functional integrity of vehicles, particularly complex designs like Mercedes-Benz models.

In today’s advanced automotive landscape, the role of electronic measuring equipment is indispensable in collision repairs. These precision tools empower technicians with unparalleled accuracy, revolutionizing traditional repair processes. From initial damage assessment to final quality control, electronic measuring equipment enhances efficiency and safety. Understanding these devices, their capabilities, and the impact they have on collision repair services is crucial for both professionals and consumers alike.

- Understanding Electronic Measuring Equipment: Tools for Precision

- Impact on Collision Repair Processes and Efficiency

- Ensuring Safety and Quality Through Advanced Technology

Understanding Electronic Measuring Equipment: Tools for Precision

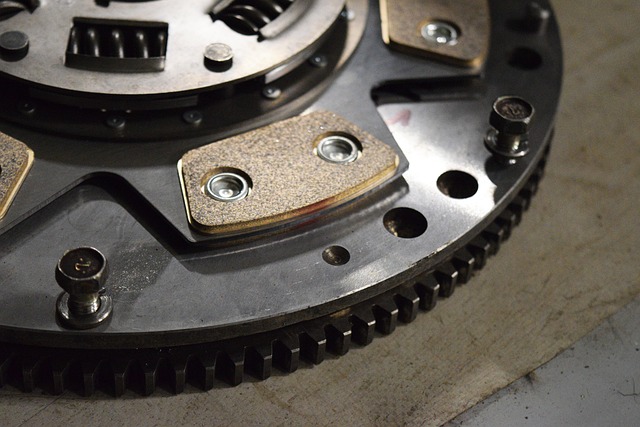

In the realm of collision repairs, precision is paramount to ensure vehicles return to their pre-accident condition. This is where electronic measuring equipment plays a pivotal role. These advanced tools are designed to provide accurate and detailed measurements, enabling repair technicians to make informed decisions during the restoration process. By employing electronic measuring equipment, such as laser scanners and digital calipers, professionals can accurately assess damage in various components like car dent repairs, hail damage repairs, and auto glass repairs.

The integration of this technology offers several advantages. It facilitates faster and more efficient repairs by streamlining the measurement phase. Moreover, it enhances accuracy, minimizing errors that could lead to subpar outcomes. In essence, electronic measuring equipment serves as a cornerstone for achieving excellence in collision repair, ensuring vehicles not only look good but also function optimally after undergoing these intricate restoration processes.

Impact on Collision Repair Processes and Efficiency

The integration of electronic measuring equipment has revolutionized collision repair processes in automotive body shops and luxury vehicle repair centers alike. These advanced tools play a pivotal role in enhancing efficiency, precision, and overall quality control. With their ability to provide accurate measurements and real-time data, collision centers can now streamline their work flow significantly. For instance, digital measurement systems enable technicians to quickly assess damage, ensuring every component is considered before repairs commence, which minimizes errors and rework.

Furthermore, the use of electronic measuring equipment offers a level of consistency unattainable through manual methods. This precision is particularly crucial when dealing with intricate automotive designs. By accurately determining panel gaps, angles, and curves, technicians can achieve seamless body panel alignment, resulting in a more aesthetically pleasing finish. This attention to detail not only satisfies customers but also ensures the safety of vehicles post-repair.

Ensuring Safety and Quality Through Advanced Technology

In today’s world, where precision and safety are paramount in automotive repair, electronic measuring equipment plays a pivotal role, especially in collision repairs. Advanced technology ensures that every repair is carried out with meticulous attention to detail, significantly reducing the risk of errors. This is particularly crucial when dealing with complex vehicle structures, such as those found in premium brands like Mercedes-Benz collision repair centers.

By utilizing sophisticated electronic measuring tools, automotive repair technicians can accurately assess damage, verify component alignment, and guarantee that each replacement part fits seamlessly. This not only enhances the overall quality of collision repair services but also ensures the safety of the vehicle and its occupants. With these advanced tools, repairs are more efficient, precise, and reliable, setting a new standard in the industry.

Electronic measuring equipment plays a pivotal role in modern collision repairs, revolutionizing processes with its precision and efficiency. By accurately assessing damage and guiding repair procedures, these tools ensure safer, higher-quality outcomes. Embracing advanced technology not only streamlines collision repair but also enhances customer satisfaction through faster turnaround times and meticulous craftsmanship. Incorporating electronic measuring equipment is a game-changer, setting new standards in the industry for safety, efficiency, and excellence.