In today's competitive market, electronic measuring equipment is vital for ensuring product quality across diverse sectors. Its unparalleled precision enables technicians to make exact measurements, enhancing craftsmanship and consistency in areas like auto body repair. Investing in this technology leads to increased customer satisfaction, faster turnaround times, lower costs, and a competitive edge in industries such as vehicle collision repair, car body restoration, manufacturing, and pharmaceuticals, ultimately boosting business success through superior outcomes.

The impact of electronic measuring equipment on workshop success cannot be overstated. In today’s competitive market, precision is paramount for maintaining product quality and consistency. From manufacturing intricate components to mixing precise pharmaceutical formulations, accurate measurements are the cornerstone of excellence. Electronic tools streamline operations, reducing human error and saving valuable time.

This article explores how these innovations not only enhance efficiency but also provide invaluable data for informed business decisions, ultimately driving growth and ensuring long-term success in diverse industries reliant on meticulous precision.

- The Role of Precision: How Electronic Measuring Equipment Enhances Product Quality

- – Discussion on the impact of accurate measurements on product quality and consistency.

- – Examples of industries where precise measurements are critical (e.g., manufacturing, pharmaceuticals).

The Role of Precision: How Electronic Measuring Equipment Enhances Product Quality

In today’s competitive market, ensuring product quality is paramount for any shop, whether it specializes in precision engineering or auto body work like car body restoration and auto body repair. Electronic measuring equipment plays a pivotal role in achieving this goal by providing unparalleled precision. These advanced tools enable technicians to make exacting measurements, down to the smallest fraction, thereby facilitating meticulous work that was once limited to human eye and hand dexterity. With electronic measuring equipment, every detail is captured accurately, leading to superior craftsmanship and enhanced product consistency.

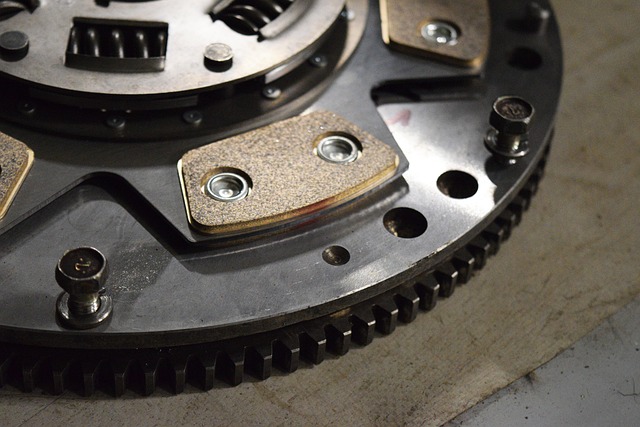

For instance, in auto body repair, precise measurements are crucial for aligning panels and ensuring a seamless finish. Electronic devices can quickly scan and map the car body, allowing repairs to be made with laser-like accuracy. This not only speeds up the restoration process but also guarantees that the final product meets or exceeds industry standards. In essence, investing in electronic measuring equipment is an investment in quality, which translates directly into increased customer satisfaction and a competitive edge for any shop in the auto body work realm.

– Discussion on the impact of accurate measurements on product quality and consistency.

In the realm of vehicle collision repair and car body restoration, the role of electronic measuring equipment cannot be overstated. Accurate measurements are pivotal for achieving high-quality outcomes in these intricate processes. By employing sophisticated technology, professionals can ensure precise dimensions, angles, and contours, leading to consistent and flawless repairs. This, in turn, enhances customer satisfaction, as vehicles return to their pre-accident condition or even surpass original specifications.

Consistent measurements also streamline the collision repair process, reducing human error and the need for time-consuming rework. For instance, electronic measuring equipment can quickly assess damage, guide precise cutting and welding, and ensure proper alignment during car body restoration. This efficiency translates into faster turnaround times, reduced labor costs, and a more competitive service offering.

– Examples of industries where precise measurements are critical (e.g., manufacturing, pharmaceuticals).

In numerous industries, precision is paramount, and the role of electronic measuring equipment cannot be overstated. Manufacturing, for instance, relies heavily on accurate measurements to ensure product quality and consistency. From dimensioning parts to detecting even the slightest defects, advanced sensors and gages enable manufacturers to maintain high standards. Similarly, pharmaceuticals demand meticulous precision in dosing and mixing to guarantee the safety and effectiveness of medications. Every milliliter and millimeter counts to prevent errors that could have severe consequences.

These industries, and many others like electronics assembly and automotive repair (including dent removal and car paint repair), benefit significantly from electronic measuring equipment’s capability to provide real-time, repeatable, and reliable data. This technology allows professionals to make informed decisions, streamline processes, and ultimately enhance their shop’s success by delivering superior products and services.

Electronic measuring equipment plays a pivotal role in ensuring your shop’s success by driving product quality and consistency. In industries like manufacturing and pharmaceuticals, where precision is paramount, accurate measurements are the cornerstone of high-quality outputs. By adopting modern electronic tools, businesses can achieve consistent results, reduce errors, and ultimately enhance customer satisfaction, solidifying their position in the market. Invest in these tools today to reap the benefits tomorrow.